FILTON, just outside Bristol, is where Britain’s fleet of Concorde supersonic airliners was built. In a building near a wind tunnel on the same sprawling site, something even more remarkable is being created. Little by little a machine is “printing” a complex titanium landing-gear bracket, about the size of a shoe, which normally would have to be laboriously hewn from a solid block of metal. Brackets are only the beginning. The researchers at Filton have a much bigger ambition: to print the entire wing of an airliner.

Far-fetched as this may seem, many other people are using three-dimensional printing technology to create similarly remarkable things. These include medical implants, jewellery, football boots designed for individual feet, lampshades, racing-car parts, solid-state batteries and customised mobile phones. Some are even making mechanical devices. At the Massachusetts Institute of Technology (MIT), Peter Schmitt, a PhD student, has been printing something that resembles the workings of a grandfather clock. It took him a few attempts to get right, but eventually he removed the plastic clock from a 3D printer, hung it on the wall and pulled down the counterweight. It started ticking.

Engineers and designers have been using 3D printers for more than a decade, but mostly to make prototypes quickly and cheaply before they embark on the expensive business of tooling up a factory to produce the real thing. As 3D printers have become more capable and able to work with a broader range of materials, including production-grade plastics and metals, the machines are increasingly being used to make final products too. More than 20% of the output of 3D printers is now final products rather than prototypes, according to Terry Wohlers, who runs a research firm specialising in the field. He predicts that this will rise to 50% by 2020.

Using 3D printers as production tools has become known in industry as “additive” manufacturing (as opposed to the old, “subtractive” business of cutting, drilling and bashing metal). The additive process requires less raw material and, because software drives 3D printers, each item can be made differently without costly retooling. The printers can also produce ready-made objects that require less assembly and things that traditional methods would struggle with—such as the glove pictured above, made by Within Technologies, a London company. It can be printed in nylon, stainless steel or titanium.

The printing of parts and products has the potential to transform manufacturing because it lowers the costs and risks. No longer does a producer have to make thousands, or hundreds of thousands, of items to recover his fixed costs. In a world where economies of scale do not matter any more, mass-manufacturing identical items may not be necessary or appropriate, especially as 3D printing allows for a great deal of customisation. Indeed, in the future some see consumers downloading products as they do digital music and printing them out at home, or at a local 3D production centre, having tweaked the designs to their own tastes. That is probably a faraway dream. Nevertheless, a new industrial revolution may be on the way.

Printing in 3D may seem bizarre. In fact it is similar to clicking on the print button on a computer screen and sending a digital file, say a letter, to an inkjet printer. The difference is that the “ink” in a 3D printer is a material which is deposited in successive, thin layers until a solid object emerges.

The layers are defined by software that takes a series of digital slices through a computer-aided design. Descriptions of the slices are then sent to the 3D printer to construct the respective layers. They are then put together in a number of ways. Powder can be spread onto a tray and then solidified in the required pattern with a squirt of a liquid binder or by sintering it with a laser or an electron beam. Some machines deposit filaments of molten plastic. However it is achieved, after each layer is complete the build tray is lowered by a fraction of a millimetre and the next layer is added.

And when you’re happy, click print

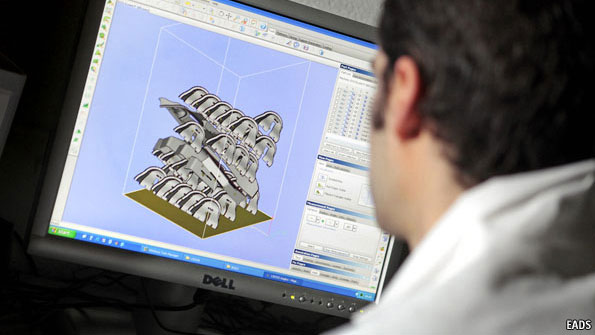

And when you’re happy, click printThe researchers at Filton began using 3D printers to produce prototype parts for wind-tunnel testing. The group is part of EADS Innovation Works, the research arm of EADS, a European defence and aerospace group best known for building Airbuses. Prototype parts tend to be very expensive to make as one-offs by conventional means. Because their 3D printers could do the job more efficiently, the researchers’ thoughts turned to manufacturing components directly.

Aircraft-makers have already replaced a lot of the metal in the structure of planes with lightweight carbon-fibre composites. But even a small airliner still contains several tonnes of costly aerospace-grade titanium. These parts have usually been machined from solid billets, which can result in 90% of the material being cut away. This swarf is no longer of any use for making aircraft.

To make the same part with additive manufacturing, EADS starts with a titanium powder. The firm’s 3D printers spread a layer about 20-30 microns (0.02-0.03mm) thick onto a tray where it is fused by lasers or an electron beam. Any surplus powder can be reused. Some objects may need a little machining to finish, but they still require only 10% of the raw material that would otherwise be needed. Moreover, the process uses less energy than a conventional factory. It is sometimes faster, too.

There are other important benefits. Most metal and plastic parts are designed to be manufactured, which means they can be clunky and contain material surplus to the part’s function but necessary for making it. This is not true of 3D printing. “You only put material where you need to have material,” says Andy Hawkins, lead engineer on the EADS project. The parts his team is making are more svelte, even elegant. This is because without manufacturing constraints they can be better optimised for their purpose. Compared with a machined part, the printed one is some 60% lighter but still as sturdy.

Lightness is critical in making aircraft. A reduction of 1kg in the weight of an airliner will save around $3,000-worth of fuel a year and by the same token cut carbon-dioxide emissions. Additive manufacturing could thus help build greener aircraft—especially if all the 1,000 or so titanium parts in an airliner can be printed. Although the size of printable parts is limited for now by the size of 3D printers, the EADS group believes that bigger systems are possible, including one that could fit on the 35-metre-long gantry used to build composite airliner wings. This would allow titanium components to be printed directly onto the structure of the wing.

Many believe that the enhanced performance of additively manufactured items will be the most important factor in driving the technology forward. It certainly is for MIT’s Mr Schmitt, whose interest lies in “original machines”. These are devices not constructed from a collection of prefabricated parts, but created in a form that flows from the intention of the design. If that sounds a bit arty, it is: Mr Schmitt is a former art student from Germany who used to cadge time on factory lathes and milling machines to make mechanised sculptures. He is now working on novel servo mechanisms, the basic building blocks for robots. Custom-made servos cost many times the price of off-the-shelf ones. Mr Schmitt says it should be possible for a robot builder to specify what a servo needs to do, rather than how it needs to be made, and send that information to a 3D printer, and for the machine’s software to know how to produce it at a low cost. “This makes manufacturing more accessible,” says Mr Schmitt.

The idea of the 3D printer determining the form of the items it produces intrigues Neri Oxman, an architect and designer who heads a research group examining new ways to make things at MIT’s Media Lab. She is building a printer to explore how new designs could be produced. Dr Oxman believes the design and construction of objects could be transformed using principles inspired by nature, resulting in shapes that are impossible to build without additive manufacturing. She has made items from sculpture to body armour and is even looking at buildings, erected with computer-guided nozzles that deposit successive layers of concrete.

Some 3D systems allow the properties and internal structure of the material being printed to be varied. This year, for instance, Within Technologies expects to begin offering titanium medical implants with features that resemble bone. The company’s femur implant is dense where stiffness and strength is required, but it also has strong lattice structures which would encourage the growth of bone onto the implant. Such implants are more likely to stay put than conventional ones.

Working at such a fine level of internal detail allows the stiffness and flexibility of an object to be determined at any point, says Siavash Mahdavi, the chief executive of Within Technologies. Dr Mahdavi is working on other lattice structures, including aerodynamic body parts for racing cars and special insoles for a firm that hopes to make the world’s most comfortable stiletto-heeled shoes.

Digital Forming, a related company (where Dr Mahdavi is chief technology officer), uses 3D design software to help consumers customise mass-produced products. For example, it is offering a service to mobile-phone companies in which subscribers can go online to change the shape, colour and other features of the case of their new phone. The software keeps the user within the bounds of the achievable. Once the design is submitted the casing is printed. Lisa Harouni, the company’s managing director, says the process could be applied to almost any consumer product, from jewellery to furniture. “I don’t have any doubt that this technology will change the way we manufacture things,” she says.

Other services allow individuals to upload their own designs and have them printed. Shapeways, a New York-based firm spun out of Philips, a Dutch electronics company, last year, offers personalised 3D production, or “mass customisation”, as Peter Weijmarshausen, its chief executive, describes it. Shapeways prints more than 10,000 unique products every month from materials that range from stainless steel to glass, plastics and sandstone. Customers include individuals and shopkeepers, many ordering jewellery, gifts and gadgets to sell in their stores.

EOS, a German supplier of laser-sintering 3D printers, says they are already being used to make plastic and metal production parts by carmakers, aerospace firms and consumer-products companies. And by dentists: up to 450 dental crowns, each tailored for an individual patient, can be manufactured in one go in a day by a single machine, says EOS. Some craft producers of crowns would do well to manage a dozen a day. As an engineering exercise, EOS also printed the parts for a violin using a high-performance industrial polymer, had it assembled by a professional violin-maker and played by a concert violinist.

Both EOS and Stratasys, a company based in Minneapolis which makes 3D printers that employ plastic-deposition technology, use their own machines to print parts that are, in turn, used to build more printers. Stratasys is even trying to print a car, or at least the body of one, for Kor Ecologic, a company in Winnipeg, whose boss, Jim Kor, is developing an electric-hybrid vehicle called Urbee.

Jim Kor’s printed the model. Next, the car

Jim Kor’s printed the model. Next, the carMaking low-volume, high-value and customised components is all very well, but could additive manufacturing really compete with mass-production techniques that have been honed for over a century? Established techniques are unlikely to be swept away, but it is already clear that the factories of the future will have 3D printers working alongside milling machines, presses, foundries and plastic injection-moulding equipment, and taking on an increasing amount of the work done by those machines.

Morris Technologies, based in Cincinnati, was one of the first companies to invest heavily in additive manufacturing for the engineering and production services it offers to companies. Its first intention was to make prototypes quickly, but by 2007 the company says it realised “a new industry was being born” and so it set up another firm, Rapid Quality Manufacturing, to concentrate on the additive manufacturing of higher volumes of production parts. It says many small and medium-sized components can be turned from computer designs into production-quality metal parts in hours or days, against days or weeks using traditional processes. And the printers can build unattended, 24 hours a day.

Neil Hopkinson has no doubts that 3D printing will compete with mass manufacturing in many areas. His team at Loughborough University has invented a high-speed sintering system. It uses inkjet print-heads to deposit infra-red-absorbing ink on layers of polymer powder which are fused into solid shapes with infra-red heating. Among other projects, the group is examining the potential for making plastic buckles for Burton Snowboards, a leading American producer of winter-sports equipment. Such items are typically produced by plastic injection-moulding. Dr Hopkinson says his process can make them for ten pence (16 cents) each, which is highly competitive with injection-moulding. Moreover, the designs could easily be changed without Burton incurring high retooling costs.

Predicting how quickly additive manufacturing will be taken up by industry is difficult, adds Dr Hopkinson. That is not necessarily because of the conservative nature of manufacturers, but rather because some processes have already moved surprisingly fast. Only a few years ago making decorative lampshades with 3D printers seemed to be a highly unlikely business, but it has become an industry with many competing firms and sales volumes in the thousands.

Dr Hopkinson thinks Loughborough’s process is already competitive with injection-moulding at production runs of around 1,000 items. With further development he expects that within five years it would be competitive in runs of tens if not hundreds of thousands. Once 3D printing machines are able to crank out products in such numbers, then more manufacturers will look to adopt the technology.

Will Sillar of Legerwood, a British firm of consultants, expects to see the emergence of what he calls the “digital production plant”: firms will no longer need so much capital tied up in tooling costs, work-in-progress and raw materials, he says. Moreover, the time to take a digital design from concept to production will drop, he believes, by as much as 50-80%. The ability to overcome production constraints and make new things will combine with improvements to the technology and greater mechanisation to make 3D printing more mainstream. “The market will come to the technology,” Mr Sillar says.

Some in the industry believe that the effect of 3D printing on manufacturing will be analogous to that of the inkjet printer on document printing. The written word became the printed word with the invention of movable-type printing by Johannes Gutenberg in the 15th century. Printing presses became like mass-production machines, highly efficient at printing lots of copies of the same thing but not individual documents. The inkjet printer made that a lot easier, cheaper and more personal. Inkjet devices now perform a multitude of printing roles, from books on demand to labels and photographs, even though traditional presses still roll for large runs of books, newspapers and so on.

How would this translate to manufacturing? Most obviously, it changes the economics of making customised components. If a company needs a specialised part, it may find it cheaper and quicker to have the part printed locally or even to print its own than to order one from a supplier a long way away. This is more likely when rapid design changes are needed.

Printing in 3D is not the preserve of the West: Chinese companies are adopting the technology too. Yet you might infer that some manufacturing will return to the West from cheap centres of production in China and elsewhere. This possibility was on the agenda of a conference organised by DHL last year. The threat to the logistics firm’s business is clear: why would a company airfreight an urgently needed spare part from abroad when it could print one where it is required?

Our TQ article explains the technology behind the 3-D printing process

Our TQ article explains the technology behind the 3-D printing processPerhaps the most exciting aspect of additive manufacturing is that it lowers the cost of entry into the business of making things. Instead of finding the money to set up a factory or asking a mass-producer at home (or in another country) to make something for you, 3D printers will offer a cheaper, less risky route to the market. An entrepreneur could run off one or two samples with a 3D printer to see if his idea works. He could make a few more to see if they sell, and take in design changes that buyers ask for. If things go really well, he could scale up—with conventional mass production or an enormous 3D print run.

This suggests that success in manufacturing will depend less on scale and more on the quality of ideas. Brilliance alone, though, will not be enough. Good ideas can be copied even more rapidly with 3D printing, so battles over intellectual property may become even more intense. It will be easier for imitators as well as innovators to get goods to market fast. Competitive advantages may thus be shorter-lived than ever before. As with past industrial revolutions, the greatest beneficiaries may not be companies but their customers. But whoever gains most, revolution may not be too strong a word.

【英国《经济学家》2月18日一期文章】题:印刷出来的世界

在英国菲尔顿的一座建筑里,诞生了一件非凡的东西。一台机器正在一点一点地“印刷”出一个复杂的钛金属飞机起落架,而此类物品通常要从一大块金属上费力地切割出来。而起落架只是个开始。

虽然这听上去有些遥不可及,但许多人已经在用3D印刷技术来制造一些同样令人惊叹的东西,像医学移植物、珠宝、定制的足球鞋、灯罩、赛车部件、电晶体电池和定制手机等,甚至还能印刷机械设备。

工程师和设计人员应用3D印刷技术已超过十年,不过主要是用来快速制造廉价的样品,然后才启动工厂的设备生产真正的产品。随着 3D印刷机的功能越来越强大,能够使用的材料也越来越广泛(包括工业等级的塑料和金属),这种机器也更多地被用来生产制成品。调查显示,现在3D印刷的产品中超过20%都是制成品而不是样品,到2020年这一比例有望上升到50%。

业内把3D印刷技术称为“添加”式制造(相对于传统的切割、打孔或锤炼等“减”式制造法)。这种添加过程需要的原材料更少,而且,由于3D印刷机是由软件驱动的,在不费力更换硬件的情况下就能制造出不同的产品。

印刷零部件和产品有望转变制造过程,因为它能降低成本和风险。制造商不需要为了赚回成本而进行量产。3D印刷技术可以满足大量的定制需求。今后消费者可以像下载数码音乐那样下载产品,并在家或者去本地的3D生产中心生产。那也许还是个遥远的梦。但不管怎么说,一场新的工业革命可能正在悄然进行。

3D印刷听起来可能有些奇怪。事实上,这跟把电脑文件送到喷墨打印机里差不多。区别在于,3D印刷机里的“墨水”是生产材料。它们储存在很薄的连续不断的涂层里。软件通过计算机的设计选取一系列的数字切片,然后确定涂层。对切片的描述被送往3D印刷机来建设相应的涂层。然后再通过各种方式把它们组合起来。粉末被喷到一个托盘上,通过液体粘合剂的喷射或激光或电子束的焊接来塑造成需要的固体形状。

一些业内人士认为,3D印刷对制造业的意义可与喷墨打印机对文件打印的意义相提并论。